At the Naval Postgraduate School (NPS), modeling and simulation (M&S) isn’t an academic exercise; it’s a path to better, faster, safer decisions in real-world situations. By building shared digital twins, running batches of what-if tests, and letting operators and engineers adjust the same model together, NPS teams pull months and years out of planning and reduce risk before anyone touches a flight line or flips a switch on an installation.

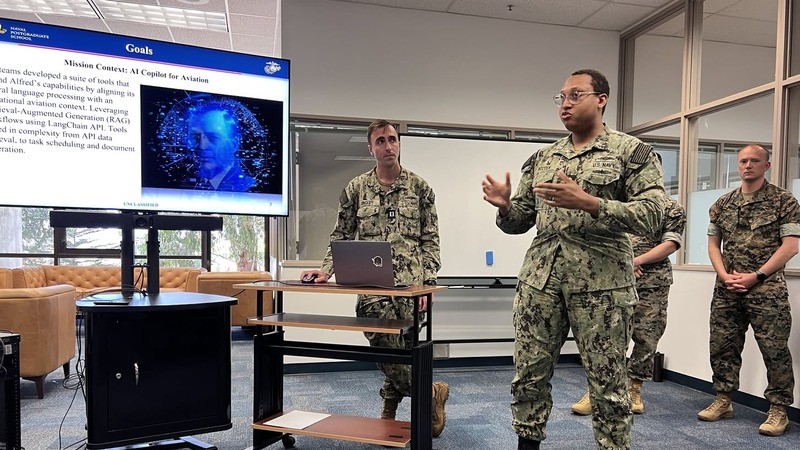

This collaborative approach underpins the NPS Artificial Intelligence Task Force (AITF), which supports artificial intelligence (AI) training and advanced AI research for public sector applications, and the Digital Trident AI Challenge, a one-year research sprint to experiment with and operationalize emerging AI technologies and advanced AI techniques.

Better decisions, faster

The value of M&S is straightforward: See it, try it, then do it – with evidence. High-fidelity virtual models, called digital twins, help teams visualize complex systems, test trade-offs, rehearse edge conditions, and create trustworthy data for AI when real data is scarce or sensitive. For missions from aviation maintenance to base energy planning, this means fewer false starts and more confident decisions.

“Modeling and simulation can enhance things you already do. It plays out real-world scenarios – often faster than real time – so teams can efficiently evaluate multiple options and make more effective decisions in a shorter time horizon,” said U.S. Army Lt. Col. Charlie Rowan, Ph.D., who directs the Modeling, Virtual Environments, and Simulation Institute at NPS.

Perry McDowell, a faculty associate who teaches modeling and simulation to mid-career officers and civilians, shared an example. “When I was in the Navy, I spent a lot of time in shipyards. Many tasks needed to be performed in a specific location, and they couldn’t be done concurrently. The different shops would spend tons of time in meetings trying to plan out the work. If you could use modeling and simulation to understand shipyard availability before you brought the ship into the shipyard, you could deconflict everything and have a lot less rework.”

Human-centered by design, supported by industry

At NPS, the operator – like McDowell’s shipyard servicemember, for example – is a co-designer with engineers and leaders. Operator end users help establish what “good” looks like, steer scenarios, and critique results in the model. Through the shared model, students build the same picture of the problem and the same language to talk about it, which speeds adoption when it’s time to deploy, Rowan said.

NPS’ partnership with NVIDIA formalized a playbook for co-building: The NVIDIA AI Tech Center on campus, one of only two nationwide, gives students, researchers, and operators a shared, hands-on space with modern hardware and platforms like NVIDIA Omniverse, which is used for building and operating 3D applications and services.

Dell Technologies and Sterling support the effort with hardware, storage, and systems integration. In practice, that means learners and project teams can scale their models from a laptop to Dell GPU clusters and, for larger problems, to an incoming rack-scale NVIDIA platform, McDowell noted.

“At Sterling, our focus is on turning technology into tangible results. Our cleared engineers work side by side with partners like the Naval Postgraduate School to deploy, optimize, and scale the systems that transform innovation into operational advantage,” said Chris Cyr, chief technology officer, Sterling.

The partnership also powers Digital Trident sprints: Industry is a co-builder alongside operators and faculty, contributing hardware, software, and expertise while students learn on production-grade tools. The result is a tighter loop between training and doing: Models are validated in Omniverse, moved onto Dell/NVIDIA compute for heavier lifting, and transitioned faster to the operator’s world, with governance and security built in from the start.

“The beauty is that students are learning with the same tools they’ll use in the fleet,” Rowan said.

As an example, NPS is taking an AI factory approach – implementing an end-to-end operational framework for AI – and that approach will be backed by the Dell AI Factory with NVIDIA, a validated platform that includes everything from hardware to services, capable of running multiple AI workloads.

“Dell’s AI Factory provides a secure, scalable foundation for turning innovation into operational impact,” said John Garrett, vice president, Department of War, Dell Technologies. “The Naval Postgraduate School is showing how open, modular infrastructure enables operators, engineers, and students to collaborate at speed and scale – moving from isolated pilots to mission-driven outcomes.”

Affordability, efficiency, and scale

U.S. Marine Corps Maj. Dillon Pierce, senior technical research analyst at NPS, researches affordable, scalable missile architectures. M&S helps teams to address system cost and scale up front, he noted.

“Everything’s a design trade,” he said. “You’re balancing things like producibility, cost, and performance. AI-enabled modeling and rapid iteration allow us to selectively and explicitly design a system to achieve the same functionality as traditional, high-end capabilities at orders of magnitude reduction in cost.”

Rowan agreed. “We have to find efficiencies,” he said. “The folks who leverage Omniverse for creating synthetic data and building and training models inside the synthetic world are saving huge amounts of time and money. This is the direction we need to move if we want to be more efficient – and more effective, faster.”